Bilge keel and stabilizers are often damaged by floating or submerged objects or by accidental grounding. Alpha Subsea can mobilize quickly and perform emergency repairs on these to prevent further damage with the use of cutting and burning equipment as well as crack arresting by drilling and underwater welding techniques to complete either temporary or permanent class-approved repairs in a timely and cost-effective manner.

Alpha Subsea has a vast amount of fiber optic cable installation and repair experience. Our personnel have worked on every one of the many cables landed on both coasts of Panama in the late 90’s as well as on many other projects worldwide. Alpha Subsea has the capability to plan, coordinate, implement and complete any fiber optic landing, repair, reroute, re-burial or remedial work utilizing barges, supply boats and dive support vessels in conjunction with subsea anchoring systems to place cable safely and accurately along the designated cable route. We have successfully completed many inshore cable route surveys to ensure cable is routed through optimal areas to minimize danger to the cable and reduce environmental impact of the cable on marine ecosystems. We also have extensive experience with all types of heavy machinery such as excavators and winches etc. for beach and shore work. Our personnel have worked with internationally recognized fiber optic cable specialists such as UTS (Underwater Technical Services), Global Marine, Maritech, Kraken Marine, Alcatel-Lucent, Level 3, Tyco and more.

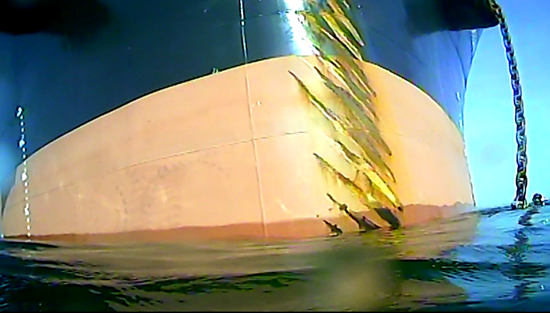

Alpha Subsea provides the very best hull cleaning services, operating on both sides of the Panamanian isthmus we offer-all-year-round hull cleaning service. Our teams operate within the protected shelter of the Balboa Anchorage on the Pacific entrance to the Panama Canal and in the Cristobal inner anchorage at the Atlantic entrance as well as other key locations along Panama’s coastline and select International ports. Rapid turnaround cleanings can be provided in as little as 12 hours depending on the size of the vessel and the extent of the fouling.

Alpha Subsea’s twin brush mobile system enables the vessel’s hull to be cleaned in a short time enhancing the vessel’s performance by reducing drag and therefore fuel costs and reduces voyage times as well as engine wear.

Alpha Subsea’s equipment consists of mobile, diver-operated, hydraulic-driven, rotary twin-brush cleaning units. We have a wide range of brushes available to handle any type of marine fouling and select the softest brushes possible to enable us to clean the hull effectively without damage to the paint or antifouling system. The brush pressure and speed are adjustable by the diver for optimal cleaning effect and meet the parameters of the most sensitive coating systems to produce exactly the type of cleaning action required. The brush bristles lay flat against the hull, cleaning it with a sweeping motion.

Alpha Subsea’s personnel have many hours of hands-on experience working and maintaining the underwater portions of hydroelectric dams which present a number of unique challenges when it comes to operations and maintenance. The use of commercial divers where it is safe to do so is one of the best and cost effective options for inspecting or maintaining these portions of the dams instead of being forced to dewater them.

These tasks are becoming larger in scope at many facilities as the hydroelectric assets age. After years of operation, these facilities can begin to deteriorate and require proactive repair and maintenance programs. Hydroelectric generating companies generally consider all possible options to extend the lifespan of existing assets, especially those that are underwater and are often harder to address. Because the underwater infrastructure is critical in generating power, controlling flow, addressing associated environmental concerns, as well as maintaining profitability, maintenance to these assets is critical to avoid possible outage times or other undesired effects.

Some of the maintenance and repair issues some dams are facing today are; replacement or refurbishment of internal gates and valves, debris inspections and clearance, sediment build-up which must be removed etc.

To avoid dewatering at hydro facilities, many repairs can be accomplished by using experienced commercial dive teams with the latest in underwater equipment. These teams can work very effectively, and can perform a great number of maintenance and repair operations.

Alpha Subsea personnel have also worked on a number of underwater bridge inspections and maintenance, and repair projects and have a wealth of experience in this field.

The underwater inspection of the bridge structure, piles, piers, and abutments is an important part of the maintenance which needs to be carried out on a periodical basis in order to avoid costly repairs and in worst case scenarios bridge failure. We provide custom-made in-depth reports for engineers which contain a condition report with photographic and video evidence when required. We can also perform live CCTV inspection where the engineers can see the condition of the structure first-hand.

Some of our maintenance methods include, cleaning or removing marine growth from underwater structures, band Installation, Denso wrapping, pile wrapping, core sampling, installing cathodic protection, scour repair, and erosion control with the use of gabions and concrete mattresses.

In Water Hull Damage Repairs: Alpha Subsea specializes in underwater engineering solutions including welding, cutting and burning for a wide range of in-water damage repairs, including those caused by grounding, collision and corrosion.

Our services cover engineering design, manufacturing, procurement, diving support and project management. On larger contracts we work closely with international underwater repair experts to assure the highest quality and timeliness of the repairs.

Most work traditionally carried out in a dry dock can be done afloat and in-water by using a number of underwater engineering techniques. This can save the customer time and money and is often an attractive alternative to dry docking.

Alpha Subsea has successfully completed many repairs in Panama on a variety of vessels allowing them to continue their journeys in the shortest time possible. Our repairs can either be temporary or permanent and fully class approved.

In Water Surveys (IWS), should be planned regularly and are from time to time required by the International Association of Classification Societies (I.A.C.S.) to ensure the structural and operational integrity of a ship’s hull and machinery throughout its operational life span and Under Water Inspection in Lieu of Dry-docking (UWILD) are carried out periodically as and when required by the I.A.C.S. societies.

Completing these surveys with divers, while in Panama, can save ship owners and their clients both time and money by reducing downtime, limiting time off-contract, and reducing or eliminating the need for expensive dry-docking. This process includes in-water inspection utilizing divers using state of the art CCTV video recording equipment. An in-depth report is produced for the client to study and for their files.

Alpha Subsea is currently approved by several international classification societies (I.A.C.S.) to conduct these U.W.I.L.D .and I.W.S. surveys such as ABS and LR Class. Our U.W.I.L.D. and I.W.S. specialties are with all ship types. We are strategically located in Panama, with up to date, certified equipment and are able to mobilize at short notice. Our clients can be certain, that our U.W.I.L.D. & I.W.S. surveys will be executed professionally, efficiently and in line with any IACS requirements. When we conduct our U.W.I.L.D. and I.W.S surveys, we work closely with the I.A.C.S. attending surveyor, working to our established M.O.P.’s (Method of Procedures).

Our experienced divers operate from D.S.V.’s (Dive Support Vessels) using surface supplied air spreads or from land alongside while vessels are at port. All our divers are A.D.C.I. (Association of Diving Contractors International) qualified.

OVERVIEW OF OUR SURVEY SERVICES:

Class surveys, LR, ABS, approved

In-Water surveys in lieu of dry docking

CCTV Surveys

Photographic & Video surveys

Damage assessments.

Assessment of Anti-fouling paint systems

General Inspections of Hulls, Plating, Welding, Water Intakes, Propellers, Rudders, Thrusters and Bilge keels.

Tail shaft and pintle readings and measurements.

Sales Surveys / Change of ownership

Underwater paint thickness inspections

Plate thickness readings

Alpha Subsea can provide a reliable and integrated marine civil engineering service in Panama for the construction of a large variety of marine construction projects. Alpha Subsea’s capabilities are founded on the many years of experience of our team members.

We support clients and contractors in the civil engineering industry providing a first class service and at an affordable cost, with the skills and capability to perform a diverse range of marine activities on concrete and steel structures from underwater welding, cutting and burning to inspection, repairs, scour protection, installation and demolition of marine and inland water structures. We also have extensive experience providing diver dredging systems for silt clearance in ports, harbors and marinas.

Our clients can depend on us to understand and complete their projects in the shortest time possible and finding the most cost-effective solutions for their projects.

Our services include:

Outfall and pipeline installation, repair and inspection

Diving and related services including inspections of assets and structures

Marine asset installation, inspection and repair

Wet welding design, specification and installation both coded or non-coded

Corrosion prevention system installation

Quay and pile repairs such as welding of doubler plates, steel sheets and tubular piles.

Scour protection (geotextile blankets, concrete mattresses, gabions, grout mattresses)

Demolition and construction of marine structures

Detailed photographic in water survey with written report.

CCTV live video inspections.

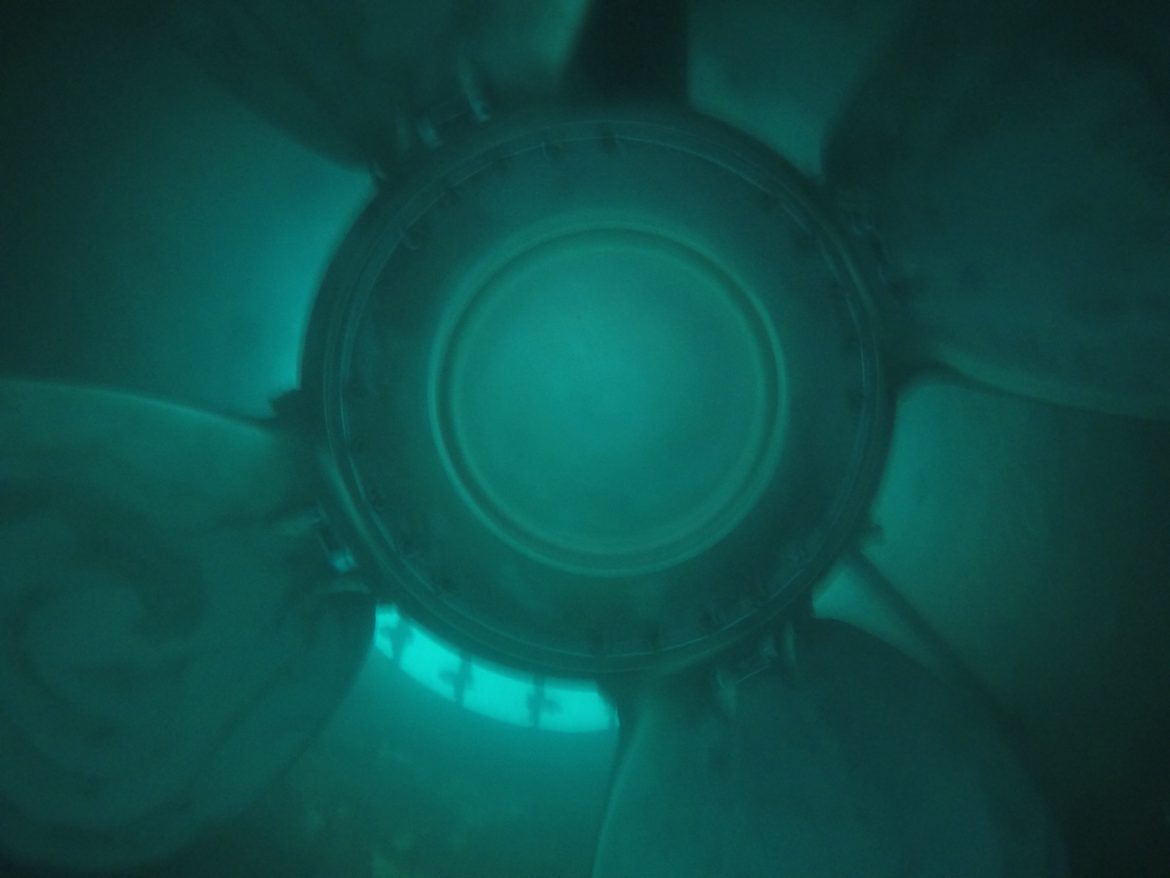

Frequent, cleaning of the propeller using hydraulic tools with polishing pads is the most effective way to keep a ship’s propeller in optimal condition. A smooth surface makes it harder for marine organisms to attach themselves as well as being beneficial to the efficiency of the propeller. A polished propeller reduces the chances of cavitation damage. Not allowing a calcareous layer of marine growth to build up is actually the best approach to propeller maintenance, avoiding the use of highly abrasive pads needed for the removal of calciferous growth which has the potential to damage the propeller surfaces. If polishing is conducted on a regular basis it can result in 5% or more savings on fuel consumption. Keeping a propeller clean with regular polishing to Rubert scale B or better is where the most fuel savings are to be made.

With the high cost of fuel in the current market and cost estimated to rise in the future it makes sense to keep propellers in the best condition possible.

Alpha Subsea offers cutting edge solutions for propeller damage and associated performance problems. We are able to perform quality underwater repairs, which, in many cases are considered as 'permanent' by the Classification Societies. When necessary we work in conjunction with internationally recognized specialists to assure the best results. Our personnel have extensive experience and on-the-job training in propeller repair. We can perform propeller blade straightening, mass in-balance corrections and technical inspections. Repairs can be made during the vessel’s scheduled stop while waiting to transit the Panama Canal causing none or minimal interruption to the vessels itinerary.

If an in-water solution cannot be found the propeller can be removed by divers and placed on deck using a crane where repairs can be performed in dry conditions by internationally recognized specialists who can be flown into Panama at short notice.

OUR SERVICES INCLUDE

Underwater video inspection and detailed reporting

Straightening

New blade tips

New Propellers

Balancing of blades and fixed pitch propellers

Contour modification to correct cavitations

Edge modification, including anti-sing correction

Blade cropping

Propeller polishing

Afloat replacement of thrusters, propellers and blades

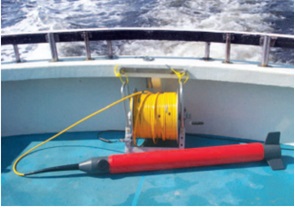

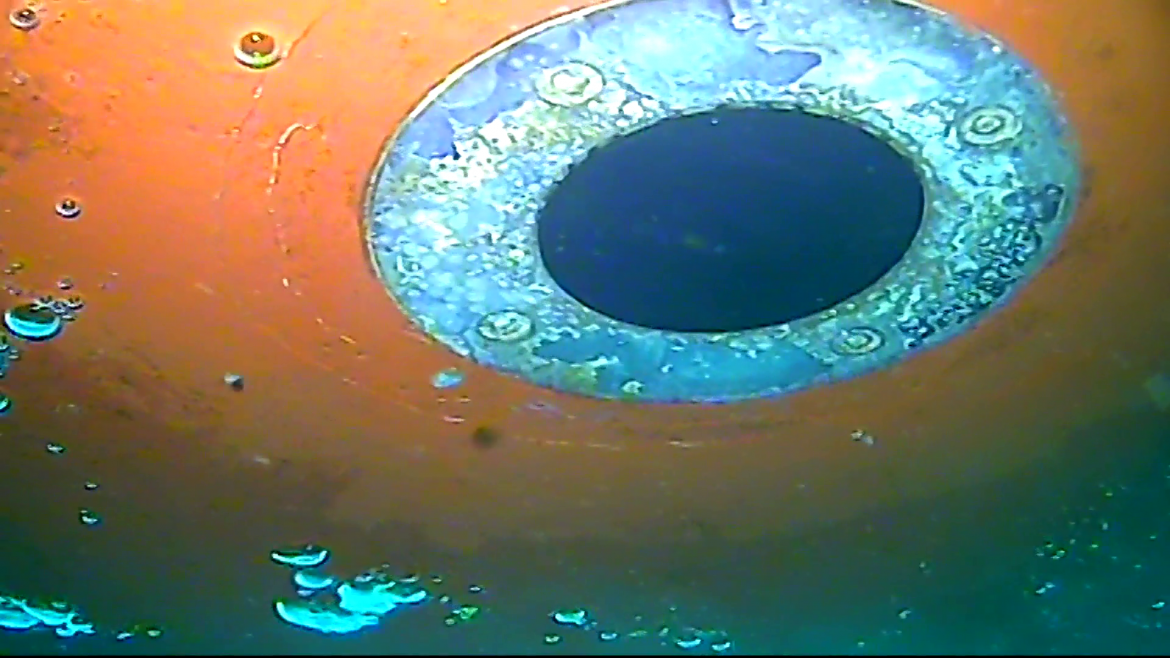

Through-hull fixtures and instruments require changing from time to time due to impact damage or gradual damage caused by the harsh marine environments they are subjected to. Alpha Subsea has extensive experience with transducer and speed log change-outs and can quickly and safely replace these items while vessels await Panama Canal transits, getting your vessel back on its way in as little time as possible without affecting voyage times

Alpha Subsea, in conjunction with internationally recognized specialists, can perform seal repairs and replacements underwater on site anywhere in Panama. By creating a dry underwater working environment (habitat) around a seal assembly we are able to replace or repair damaged seals on site. Prior to this technology dry docking was usually necessary for this kind of operation, which is costly and time consuming.

Both traditional external lip seals and internal face type seals can be repaired afloat. For the external seals found on most commercial ships, a man-entry inflatable habitat is fitted around the stern shaft to ensure that a dry environment is created for the seal replacement or repair to be performed.

The habitat can be mobilized to any port in Panama and assembled within a few hours while your vessel is at dockside or at anchorage awaiting Panama Canal Transit.

Underwater stern seal replacement and repair services include:

Lip seals, dry repair and replacement of complete systems including seal bonding

Face seal wet repairs and replacement

Stern tube sealing to facilitate inboard repacking of water lubricated stern seals

Alpha Subsea, along with our internationally-recognized specialists, offers a complete turnkey service to allow repair or replacement of both tunnel and hull-mounted thrusters and their components such as thruster blades and grilles on vessels visiting Panamanian waters. At short notice we are able to mobilize to provide a fast and efficient service to repair or replace thruster systems in a cost effective way thus avoiding off-hire periods and expensive dry docking fees.

Alpha Subsea’s team has developed an established process for the successful application of underwater coatings to vessels and subsea structures. With our many years of experience we can provide a choice of coatings for a wide variety of underwater applications from epoxy products designed for application across splash zones to paints designed for repairing hull and underwater paint systems.

Prior to the application of protective coatings below the waterline, all marine growth, loose paint and surface oxidization is removed by rotary disc preparation and/or water blasting.

This service provides a proven solution for the ongoing protection of underwater assets without the need for costly dry docking, using a range of specialist materials including anti-corrosives, antifouling, fillers and epoxy adhesives.

Typical underwater applications include:

Application of coatings to areas damaged by abrasion, shell plate repairs or anchor chaffing.

Application of protective coatings to dock structures.

Application of coatings to vessel block areas inaccessible whilst in dry dock.

Application of coatings to areas damaged by internal weld repairs.

Alpha Subsea has been involved in many successful salvage operations in Panama, including the recovery of ships, barges, work boats, pleasure craft, and other vehicles and structures which have been submerged into water or fallen to the sea floor, using tried and tested salvage techniques, in some cases making abandoned or drifting vessels fit for towing or getting them ready to make-way under their own steam.

Alpha subsea can quickly mobilize by sea, air, or land to give assistance to distressed vessels anywhere in the Republic of Panama. Our wide range of salvage equipment, welding equipment, compressors, lift bags, pumps etc. are standby 24/7.

Alpha Subsea divers have an extensive track record of underwater welding projects. There are many applications for underwater welding in shipping and the underwater construction industries and Alpha Subsea prides itself on delivering quality and time-effective solutions to our clients:

Typical underwater applications include:

Sacrificial anode replacement

Rope guard repairs

Thruster grille repairs

Rudder repairs

External doubler plates

Sealing inlet and outlet hull penetrations.

Bathymetry:

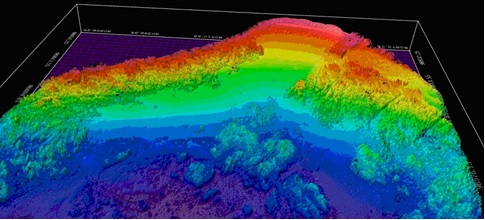

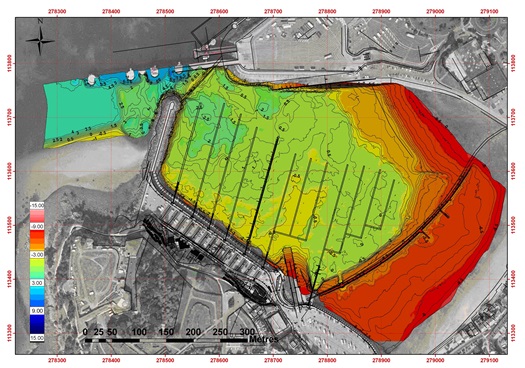

Single Beam Bathymetry: The simplest echo sounder to perform bathymetry. It is easy and fast to install on a small boat, it can measure precisely (to the centimeter) the depth at the vertical of the instruments position. To make bathymetric chart, you do parallel and perpendicular profiles spaced of 5 to 10m at the maximum speed of 5 knots. The result after data processing and modelling will be a bathymetric chart showing the general trend and morphology of the area surveyed. The amount of profiles (runs) you make will determine the accuracy of the bathymetric model. This equipment allows a full coverage of the seafloor with fewer profiles so less vessel time is required. After data processing, you will have a 3D model of the bathymetry of the seafloor.

This method is good for coverage of a big area to be surveyed. It requires a larger vessel (more than 6m) with a generator. The speed of survey is also 5 knots max. The installation 1 day for mobilization and another to demobilize.

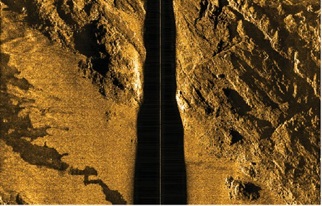

The reflectivity of the seafloor provides information on the nature the seafloor (hard or soft, smooth or rough) combined with sampling, you can draw a chart of type of sediment that covers the seafloor. It offers a view black and white of the seafloor, like a photograph, where you can distinguish the shadows of the objects, which is useful when you need to map any contact point or obstacle for your project. This instrument is towed 10m above the seafloor behind a boat and requires a winch. It can be used simultaneously along with the echo sounder bathymetry equipment. After data processing, you obtain mosaic images of the seafloor. This technique is best suited when the area to be surveyed is small, and or in shallow water or confined areas with restricted maneuverability such as harbors. It is also the most economic method.

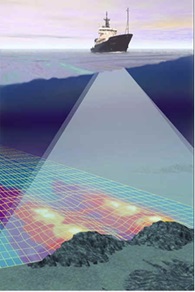

Multibeam Echo sounders are the best technology in echo sounders for bathymetry, MBES are able to measure the depth precisely at the same time in different directions. The width of the survey area where depth is measured on the seafloor is directly related to water depth at the vertical axis of the instrument on the boat. A raw estimation is five times the depth.

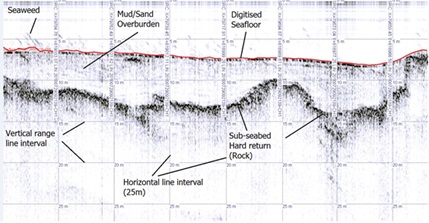

When you need information on the sediment layers and thicknesses a Sub bottom profiler is used. It can be fixed to the boat or towed behind a vessel, it measures the sediment thickness in a vertical line directly below the instrument and must be towed in a grid like pastern over the area to be surveyed. It is specifically used to detect the transition between bedrock and sediment and can penetrate up to 50m into the seabed.

The coverage will depend of the number of parallel and perpendicular profiles done.

This equipment is deployed simultaneously with the SSS in order to save time.

Is used for the detection of metallic objects on or in the seabed. The magnetometer is also deployed and towed at a low speed (2-3 knots) in a parallel and perpendicular profile.